Sustainability

Sustainability Built into Design, Manufacturing and Construction

At Exteria, sustainability is not just a buzzword; it’s the way we do things. Recognising the fragility of our environment, we’re continually reducing our carbon footprint. Every day, our team operates with a conscious focus on the environment, ensuring our products are sustainably designed, manufactured, and installed. We’re committed to responsible practices and purposeful decision-making that drives sustainability in everything we do.

We at Exteria aim at achieving continual environmental improvement through implementing a management system with objectives and targets:

Sustainable processes and products

Sustainability for us is a dual focus, both in the materials our products are made from and in the way we manufacture and install them. Internally, from our offices to warehouses, we prioritise sustainable practices, ensuring our entire ecosystem operates with minimal environmental impact. Externally, this commitment extends to our transportation practices and the meticulous selection of sustainable materials for our toilet buildings. Our dedication to sustainability resonates not only within the confines of our workspace but ripples through every aspect of our operations, reflecting our holistic approach to responsible business practices.

Sustainable materials and product options

Solar power is a popular optional add on to shelters.

Our aluminium products are recycled in Aus and contain a large percentage of recycled billet, including use of Capral’s LocAl Green aluminium which reduces carbon emissions by 50%.

We often encourage alternatives to traditional timber. Our LocAl timber-look powder coated aluminium and WPC battens are easy to maintain, durable and an eco-friendly alternative.

We adhere to the guidelines of Forests Australia. Our timber is responsibly sourced from AFSC approved suppliers, ensuring not only quality but also ethical and environmentally friendly practices.

Our aluminium products are made with a significant percentage of recycled billet, and our Vasse range is crafted entirely from recycled plastic and timber. The composite ‘wood-look’ slats offer an eco-friendly and durable solution for any public space, contributing to both sustainability and longevity.

Sustainable off-site prefabrication

How we minimise environmental impacts off-site

Our energy efficiency measures include utilising off-grid renewable energy, including solar panels at our manufacturing facility, to power our operations along with sensor LED lights and motion sensors. To further adhere to energy efficiency, all of our tools and forklifts are electric.

Our warehouse operations adhere to LEAN manufacturing principles, incorporating electric forklifts and digital processes to reduce waste.

We actively participate in recycling programs, including “containers for change,” and recycling all metal and timber offcuts.

Thoughtful planning in material orders and cutting lists minimises offcuts, and any we do generate are recycled.

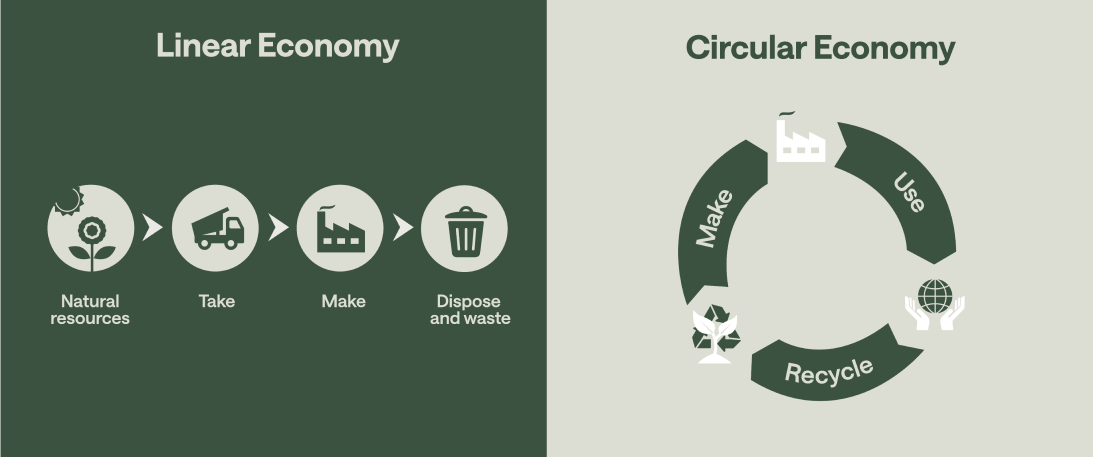

The Circular Economy

We wholeheartedly embrace the circular economy, a departure from traditional linear models. Influenced by the ideas of Michael Braungart and Bill McDonough, this systemic approach prioritises resource longevity and waste elimination. Our commitment to circular principles includes designing out waste and pollution, promoting product durability and recycling, and actively contributing to regenerating natural systems. Unlike the “take-make-waste” model, our focus is on crafting sustainable products with extended lifecycles, ensuring they can be reused, repaired, or repurposed.